The technology

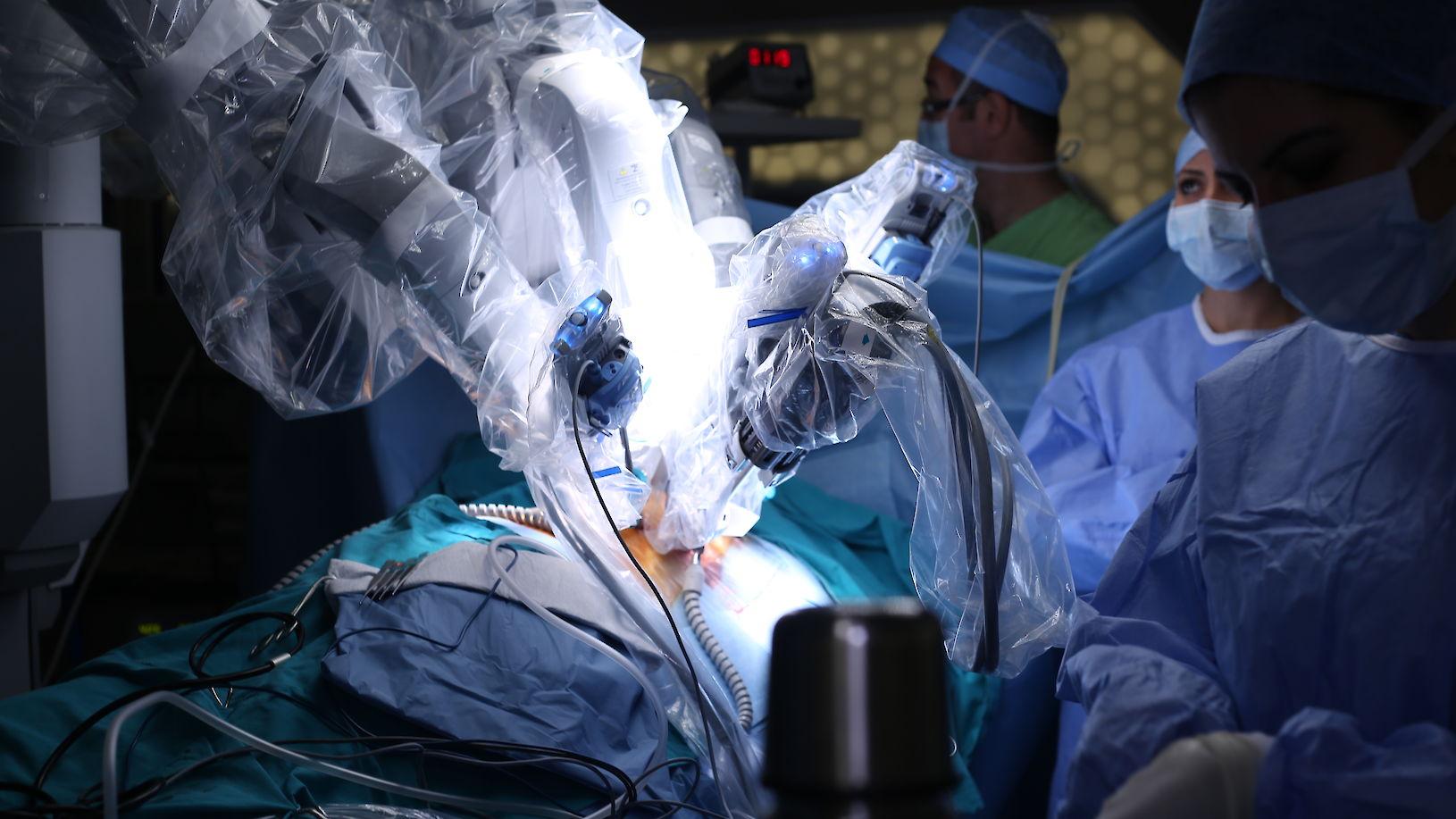

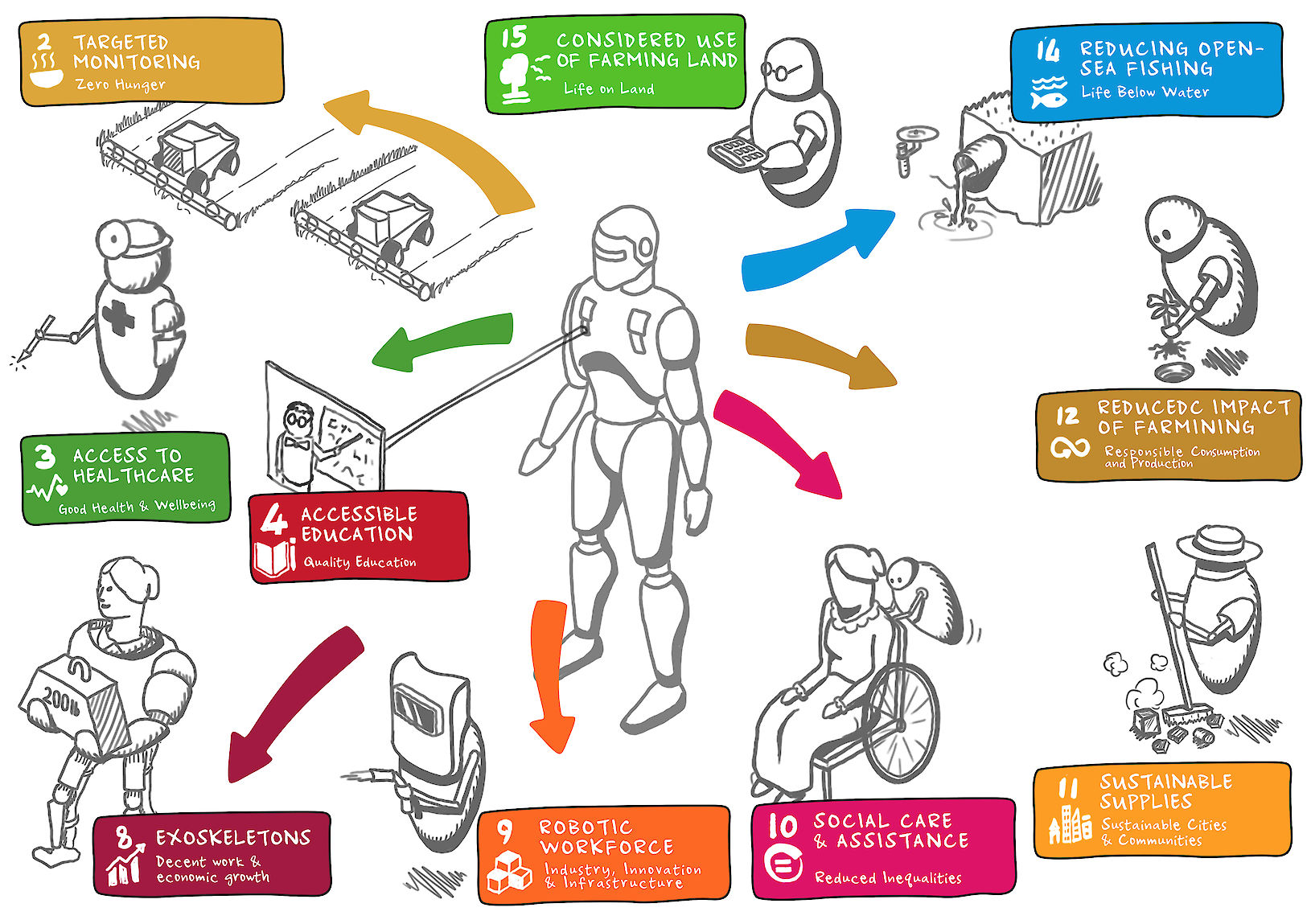

New sensors (such as cameras, distance, force and proximity sensors) now enable robots to recognise and respond to their environment. The robots can also use software and algorithms (including artificial intelligence) to interpret the data collected and to control their movement. That movement is then enabled through actuators such as wheels, grippers and robotic arms.

The potential

Robots traditionally performed repetitive, pre-programmed movements in a structured environment using simple controls. Now there is an increasing need for them to adapt to less structured and more complex, changing environments. The new generation of robot designs make it easier and safer for humans to interact and work with them in these conditions, with the potential to bring dramatic changes to the world of work.

The barriers

Automating more and more tasks using industrial robots can improve efficiency and lower production costs but are also able to reduce the number of human operators required. There are also safety and privacy concerns, with connected robots having the potential to be hacked and used to gather data or perform dangerous actions. Public perception of these factors will also be a key factor in the rate and level of uptake of this technology.